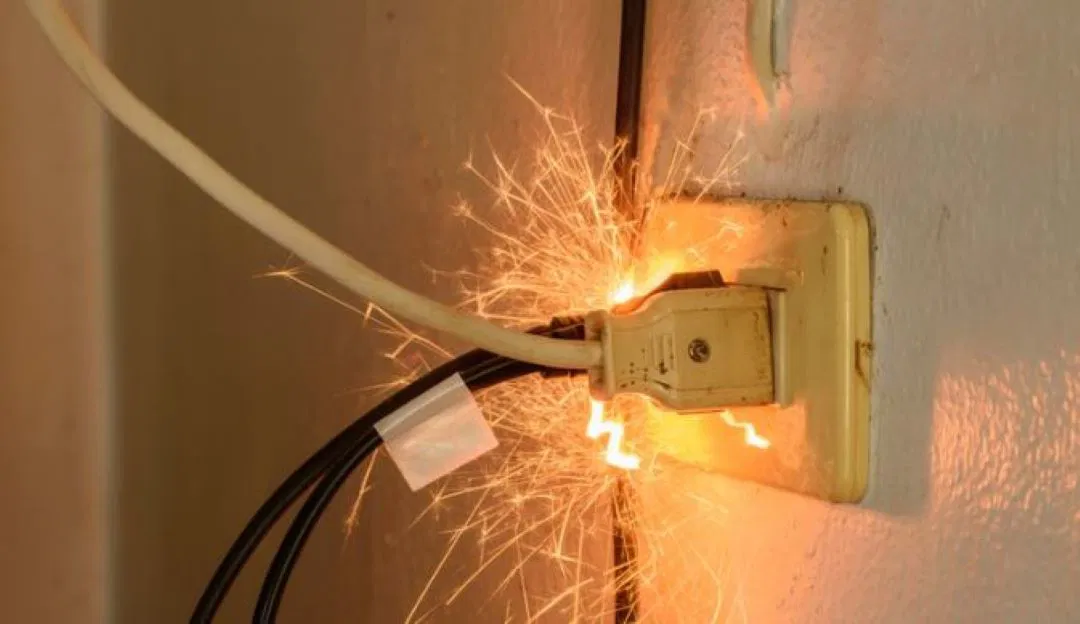

The hallmark of genuine socket cables lies in their meticulous design and the uncompromising quality of their materials. Authentic cables are manufactured using high-grade copper conductors and superior insulation materials that meet stringent international standards. The process involves advanced engineering techniques and rigorous quality control measures that guarantee consistent electrical performance and longevity. In contrast, counterfeit cables are often produced using inferior metals and low-quality polymers that not only underperform but also degrade rapidly under normal operating conditions. This degradation can lead to resistance issues, overheating, and ultimately, dangerous electrical hazards that put both property and lives at risk.

Another critical factor in identifying genuine socket cables is the presence of verifiable certifications and detailed product documentation. Established manufacturers adhere to globally recognized standards and provide comprehensive certification labels that indicate compliance with safety norms such as IEC or UL. These certifications serve as a guarantee that every aspect of the cable—from the conductor quality to the insulation integrity—has been tested under rigorous conditions. Counterfeit products, by contrast, may display forged or unverifiable labels and often lack the proper documentation that is essential for ensuring compliance with safety regulations. For any engineer or project manager, the absence of these verifiable marks should be a clear indicator of potential risk.

The manufacturing process itself provides subtle yet significant clues that distinguish authentic socket cables from their counterfeit counterparts. Genuine products are produced in state-of-the-art facilities that employ cutting-edge technology to ensure precise tolerances and consistent quality. The attention to detail is evident in every facet of the cable, from the uniformity of the insulation layer to the flawless connections at the terminals. On the other hand, counterfeit cables are typically manufactured in unregulated environments where cost-cutting measures lead to shortcuts in quality assurance. These compromises can result in irregularities and defects that may go unnoticed until they culminate in critical failures during operation.

Understanding these differences is more than a matter of technical specification—it is a critical component of risk management and operational safety. When procuring socket cables, professionals must adopt a rigorous approach to supplier evaluation, including verifying the authenticity of certifications, scrutinizing product packaging, and cross-referencing technical specifications with manufacturer standards. This level of diligence not only protects against the financial burdens of premature equipment failure but also shields the operational environment from the severe consequences of electrical hazards.

The decision to invest in genuine socket cables is an investment in the safety, efficiency, and long-term reliability of any engineering project. As the stakes continue to rise in today’s fast-paced industrial landscape, ensuring that every component meets the highest standards is paramount. The insights shared here are based on decades of engineering experience and are intended to serve as a robust guideline for making informed, safety-first decisions. Every engineer, whether seasoned or just beginning their career, must appreciate the critical importance of distinguishing authentic components from counterfeit ones.

If you found these insights valuable and are eager to deepen your understanding of quality assurance in industrial components, I encourage you to join our community at epci.ng. By signing up, you will gain exclusive access to expert advice, comprehensive technical resources, and the latest trends in innovation, production, and industrial engineering. Let us come together to elevate our standards and ensure that every project is underpinned by safety, excellence, and precision.

Leave feedback about this