The mechanical Engineering, Procurement, Construction, and Installation (EPCI) sector is evolving rapidly, driven by advancements in materials science and cutting-edge manufacturing processes. As industries demand more efficient, durable, and high-performance components, EPCI firms must integrate innovative materials and advanced production techniques to stay competitive. The future of mechanical EPCI hinges on the ability to leverage next-generation materials, automation, and sustainable manufacturing strategies to enhance project efficiency and product longevity.

Advanced materials such as high-performance alloys, composites, and smart materials are revolutionizing mechanical EPCI. Superalloys with enhanced thermal and corrosion resistance are increasingly used in aerospace, automotive, and energy applications. Carbon fiber-reinforced composites, known for their lightweight and high-strength properties, are transforming structural components, reducing overall weight while maintaining durability. Smart materials, including shape-memory alloys and self-healing polymers, are paving the way for intelligent engineering solutions that adapt to environmental conditions and extend the lifespan of mechanical systems.

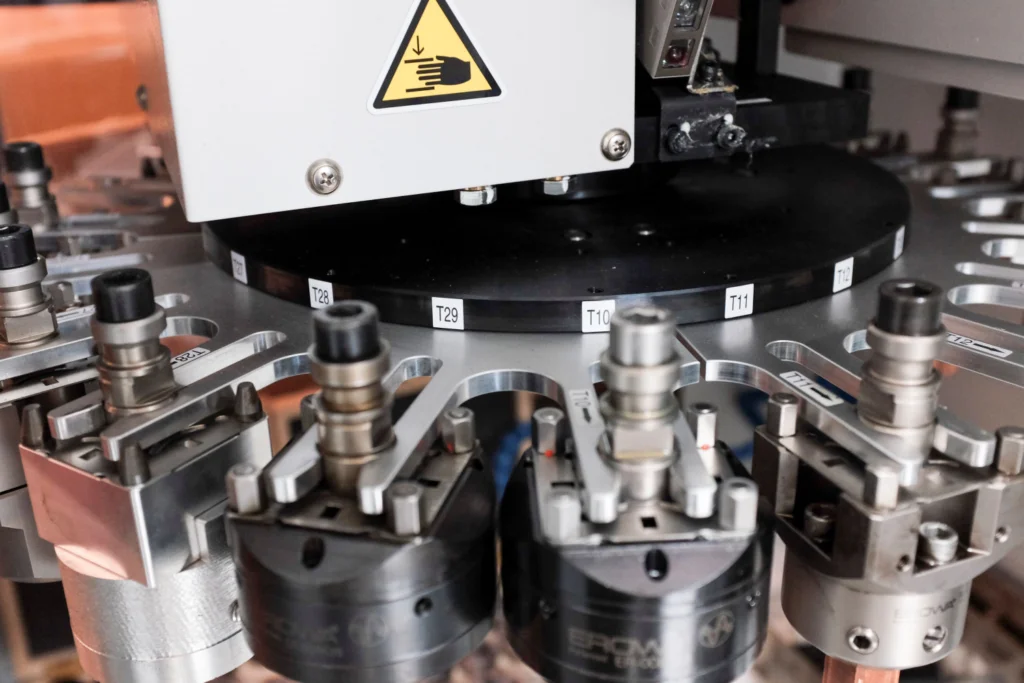

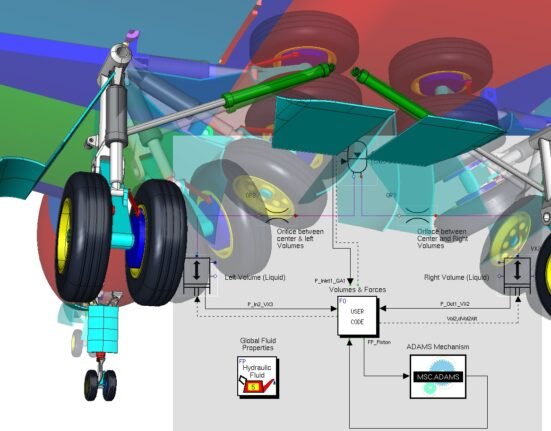

Manufacturing processes have also seen significant innovations, with additive manufacturing (3D printing) leading the charge in mechanical EPCI. This technology enables rapid prototyping, customized component fabrication, and reduced material waste, streamlining project execution. Advanced machining techniques, such as laser cutting, electron beam welding, and precision CNC machining, enhance production accuracy, allowing for intricate designs and high-tolerance assemblies. Automation, including robotics and AI-driven production lines, is further optimizing manufacturing efficiency, minimizing human error, and accelerating delivery timelines.

Sustainability is a critical consideration in modern mechanical EPCI, with a shift towards eco-friendly materials and energy-efficient manufacturing. The adoption of biodegradable composites, recycled metals, and low-carbon production methods is gaining traction across industries. Circular manufacturing principles, which focus on reusing and repurposing materials, are helping companies reduce environmental impact while improving cost efficiency.

Challenges in implementing these advancements include high initial investment costs, material availability, and the need for skilled labor proficient in next-gen technologies. However, companies that invest in research and development, digital transformation, and workforce training will lead the way in mechanical EPCI, ensuring resilience and technological leadership in the evolving industrial landscape.

Stay at the forefront of mechanical EPCI innovations. Subscribe to EPCI.ng for expert insights, industry trends, and groundbreaking advancements shaping the future of engineering and manufacturing.

Leave feedback about this