Simulation and analysis are transforming Mechanical Engineering, Procurement, Construction, and Installation (EPCI) projects by enhancing precision, efficiency, and reliability. As industries demand higher performance and reduced risks, integrating advanced simulation tools and analytical methodologies ensures optimal design, streamlined construction, and improved operational outcomes. Mechanical EPCI firms that leverage simulation-driven approaches gain a competitive edge by minimizing errors, reducing costs, and accelerating project timelines.

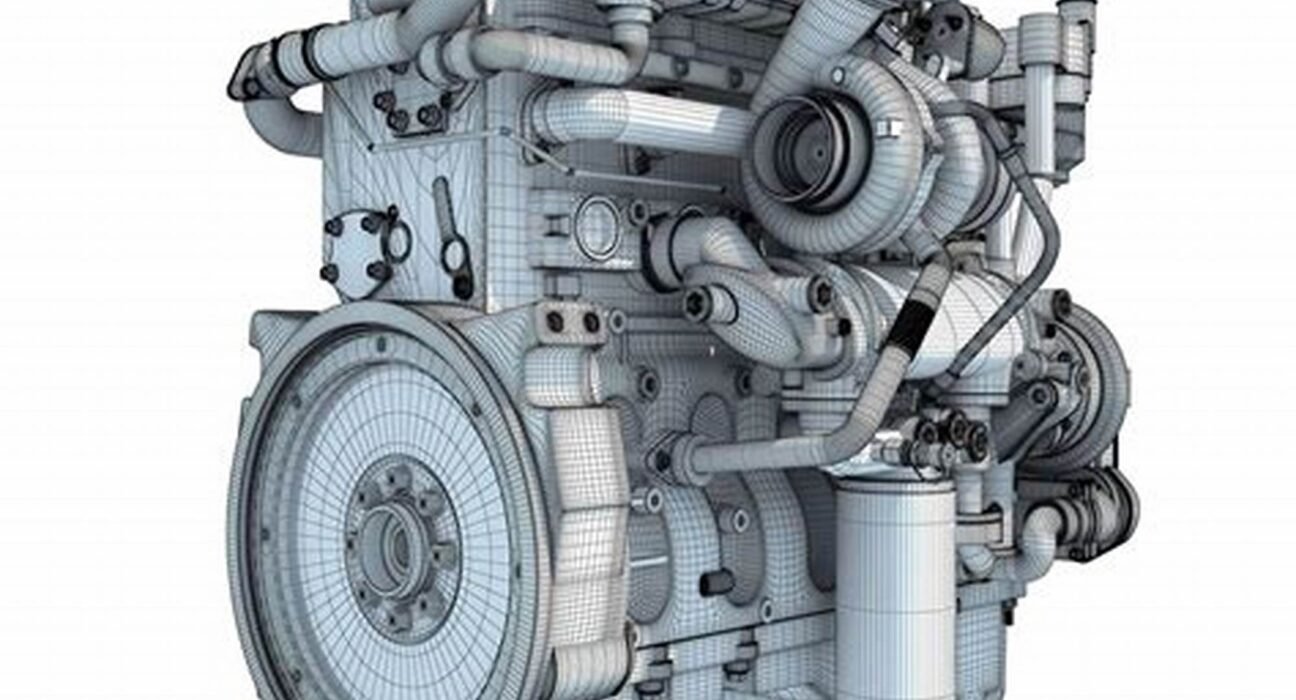

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are two essential simulation techniques in mechanical EPCI. FEA enables engineers to evaluate stress distribution, structural integrity, and material behavior under varying conditions, preventing failures before fabrication. CFD allows for the analysis of fluid flow dynamics, optimizing thermal management, aerodynamics, and cooling strategies for complex systems. These simulation tools facilitate data-driven decision-making, reducing the need for costly physical prototypes and ensuring that designs meet industry standards.

Digital twin technology is further revolutionizing mechanical EPCI by creating real-time, virtual replicas of physical assets. These digital models continuously update based on operational data, enabling predictive maintenance, performance optimization, and enhanced system reliability. By integrating simulation and real-world monitoring, EPCI firms can identify potential issues before they escalate, improving asset longevity and reducing downtime.

Structural and thermal simulations are also critical for evaluating component durability and energy efficiency. Advanced modeling techniques help engineers assess material performance under extreme conditions, ensuring compliance with safety regulations and environmental sustainability goals. With increasing emphasis on green engineering, simulation aids in designing energy-efficient systems and reducing carbon footprints across mechanical EPCI projects.

Despite its advantages, implementing simulation in EPCI projects presents challenges, such as software integration complexities, high computational demands, and the need for specialized expertise. However, organizations that invest in robust simulation frameworks, skilled professionals, and cutting-edge analytical tools will drive innovation and efficiency in the mechanical EPCI sector.

Stay ahead in mechanical EPCI with the latest simulation and analysis innovations. Subscribe to EPCI.ng for expert insights, industry trends, and groundbreaking advancements shaping the future of engineering.