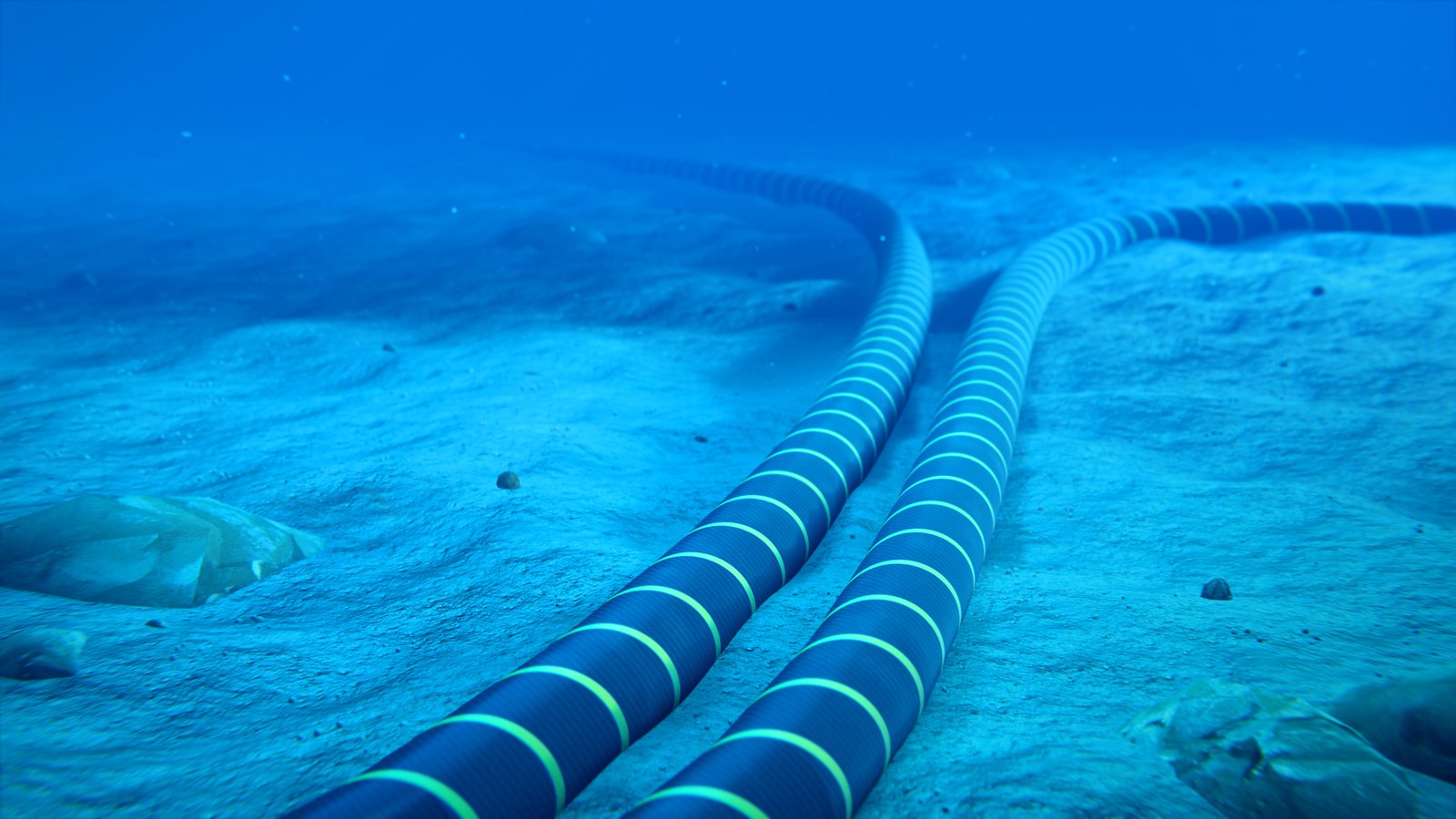

Subsea cable installation is a critical component of offshore Engineering, Procurement, Construction, and Installation (EPCI) projects, facilitating power transmission, telecommunications, and subsea infrastructure connectivity. In Nigeria’s offshore oil and gas, renewable energy, and telecommunication sectors, effective subsea cable installation ensures reliability, efficiency, and longevity. Engineers involved in offshore projects must navigate complex environmental conditions, high-pressure depths, and challenging seabed terrains to ensure successful deployments.

Understanding Subsea Cable Installation in Offshore EPCI Projects

Subsea cables serve as vital links for offshore platforms, wind farms, and underwater communication networks. Their installation requires meticulous planning, specialized vessels, and advanced engineering techniques. Offshore EPCI professionals must address technical challenges such as cable tensioning, burial depth, route optimization, and subsea jointing to prevent failures and maximize operational performance.

Cable-laying operations begin with route surveys, where engineers assess seabed conditions, geological formations, and potential hazards like shipwrecks or existing infrastructure. Advanced sonar technology and remotely operated vehicles (ROVs) play a crucial role in mapping the seabed, identifying optimal routes, and mitigating risks associated with cable damage or environmental impact.

Key Techniques for Subsea Cable Laying

Subsea cable installation techniques vary based on project specifications, water depth, and environmental factors. Engineers employ different methods, including surface-lay, plowing, and jetting, to achieve optimal burial and protection against external threats such as trawling activities, seabed movement, and anchor drag.

Surface-lay installation is commonly used for deepwater applications, where cables are laid directly on the seabed without burial. This technique requires precision tension control to prevent excessive slack, which could lead to mechanical stress and premature failure. In contrast, trenching and burial methods, including plowing and jetting, provide additional protection for cables in shallower waters by embedding them into the seabed to shield against mechanical damage and hydrodynamic forces.

Cable Protection and Integrity Management

Ensuring the long-term integrity of subsea cables is paramount in offshore EPCI projects. Engineers implement protective measures such as armored cables, rock dumping, and concrete mattresses to shield installations from external damage. Advanced real-time monitoring systems, including distributed temperature sensing (DTS) and fiber optic sensors, enable early detection of potential faults, temperature variations, and stress points along the cable route.

Effective integrity management includes periodic inspections using autonomous underwater vehicles (AUVs) and ROVs equipped with high-resolution cameras and sonar imaging. These inspections help identify anomalies such as cable fatigue, insulation degradation, and external abrasions, allowing for timely maintenance and mitigation strategies.

Challenges in Subsea Cable Installation

Offshore EPCI engineers face several challenges during subsea cable installation, including harsh weather conditions, deepwater pressure, and complex seabed topography. Strong ocean currents and unpredictable wave patterns can complicate cable-laying operations, requiring precise dynamic positioning systems and advanced vessel stabilization technologies.

Another critical challenge is cable repair and maintenance in deepwater environments. When faults occur, engineers must deploy specialized intervention techniques, including subsea cutting, splicing, and jointing operations. These repairs demand highly skilled personnel, precision-engineered tools, and state-of-the-art ROVs to restore cable functionality without disrupting offshore operations.

Quality Control and Compliance Standards

Ensuring compliance with international standards and regulatory frameworks is essential in subsea cable installation projects. Offshore EPCI professionals must adhere to guidelines set by industry bodies such as the International Electrotechnical Commission (IEC), the International Cable Protection Committee (ICPC), and the American Bureau of Shipping (ABS). Compliance with these standards ensures that cable systems meet durability, safety, and environmental sustainability criteria.

Quality control measures, including factory acceptance testing (FAT), system integration testing (SIT), and post-lay burial assessment surveys, verify cable performance before and after deployment. These rigorous testing procedures minimize the risk of operational failures and enhance the reliability of offshore cable networks.

Future Trends in Subsea Cable Installation

Advancements in subsea cable technology continue to shape the future of offshore EPCI projects. The integration of high-voltage direct current (HVDC) transmission systems, smart cables with self-diagnostic capabilities, and robotic-assisted installation techniques are revolutionizing the industry. These innovations improve efficiency, reduce installation time, and enhance real-time monitoring of cable performance.

As Nigeria expands its offshore energy and telecommunication infrastructure, investing in cutting-edge subsea cable installation technologies will be crucial for sustaining economic growth and connectivity. Engineers must stay abreast of emerging trends, collaborate with industry leaders, and adopt best practices to ensure successful project execution.

Conclusion

Subsea cable installation is a complex yet indispensable aspect of offshore EPCI projects. By leveraging advanced engineering techniques, robust protection strategies, and stringent quality control measures, Nigerian engineers can enhance the resilience and longevity of subsea cable networks. As offshore industries evolve, continuous innovation and adherence to best practices will be essential for overcoming challenges and optimizing subsea infrastructure performance.

Enhance your expertise in offshore engineering by staying updated with industry-leading insights. Sign up on epci.ng today for exclusive access to professional resources, training, and the latest advancements in subsea cable installation.

Leave feedback about this