Engine scopes, also known as borescopes or inspection cameras, are essential tools for diagnosing internal engine problems without disassembling the entire system. These devices allow engineers and technicians to visually inspect hard-to-reach areas such as cylinders, pistons, valves, and other engine components. Choosing the right engine scope is critical for accurate diagnostics and efficient maintenance in industries like aerospace, automotive, and heavy machinery.

Understanding Engine Scopes and Their Importance

Engine scopes are used to perform non-invasive inspections, allowing professionals to identify wear, damage, and other internal defects. For aerospace applications, precision is paramount because even minor flaws in engine components can lead to catastrophic failures. In automotive and industrial environments, engine scopes help identify carbon buildup, cracks, and other mechanical issues that affect performance and safety.

By using an engine scope, you save time and reduce costs by avoiding unnecessary engine disassembly. Modern engine scopes offer high-resolution imaging, advanced lighting systems, and flexible probe designs, making them invaluable for both routine inspections and complex diagnostics.

Types of Engine Scopes and Their Applications

Understanding the different types of engine scopes is crucial when selecting the best tool for your specific needs. Each type is designed for different inspection environments and provides unique advantages for various industries.

Rigid engine scopes feature a solid, non-flexible probe that provides a clear and stable image. These scopes are ideal for inspecting straight pathways and open areas where flexibility is not required. They offer high optical clarity, making them suitable for precision inspections in aerospace and laboratory environments.

Flexible engine scopes use an articulated cable that can navigate around bends and through narrow spaces. This type is particularly useful for inspecting curved components like intake manifolds, turbine blades, and combustion chambers. Flexible scopes are widely used in both automotive and aerospace sectors for their versatility and reach.

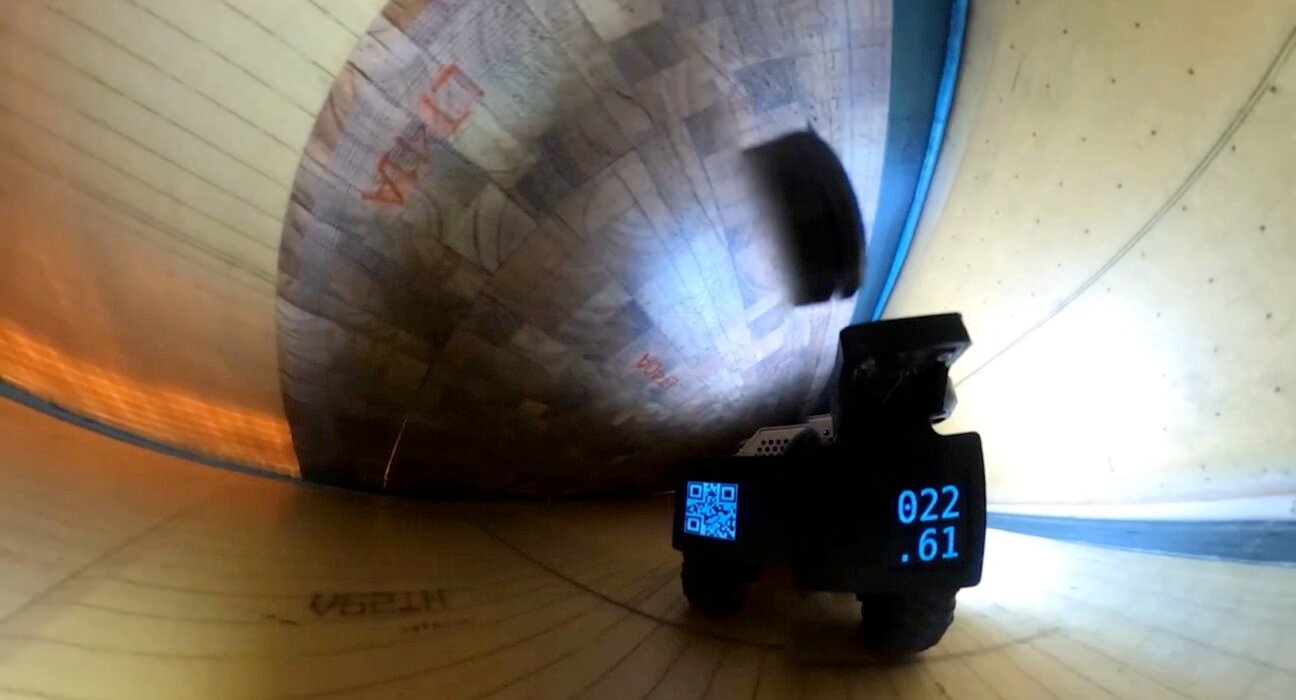

Video borescopes integrate a digital camera that transmits real-time images to a display screen. These advanced scopes provide superior image quality, video recording capabilities, and enhanced illumination. They are perfect for comprehensive inspections, enabling technicians to document findings and share visual data for analysis.

Wireless engine scopes offer the convenience of remote inspection by transmitting images to smartphones, tablets, or computers. These portable devices are ideal for fieldwork and on-the-go diagnostics, providing flexibility without being tethered to a fixed display.

Key Features to Consider When Choosing an Engine Scope

Image quality is a crucial factor when selecting an engine scope. High-resolution imaging enables precise defect identification, especially in aerospace applications where even the smallest irregularity matters. Look for scopes with at least 720p resolution for clear visuals, although 1080p and higher deliver superior detail.

Probe diameter and length determine the scope’s ability to access tight spaces. For intricate inspections, a thinner probe (between 3.9mm to 8mm) is ideal. Longer probes, ranging from 1 to 3 meters, allow for deep inspections in large engines or industrial machinery.

Illumination is essential for inspecting dark, enclosed areas. LED lighting provides bright, adjustable illumination, allowing you to examine fine details. Advanced scopes offer variable brightness settings to adapt to different inspection environments.

Durability and environmental resistance are critical for professional use. Choose a scope with a robust, waterproof design to withstand harsh conditions. Aerospace and heavy machinery environments often expose tools to oil, fuel, and extreme temperatures, requiring a rugged and resilient build.

Recording and data storage capabilities are valuable for documentation and further analysis. Many modern engine scopes feature built-in memory or SD card slots to save images and videos. This function is useful for tracking wear patterns, sharing findings, and ensuring compliance with maintenance protocols.

Choosing the Right Engine Scope for Specific Applications

In aerospace engineering, where precision and documentation are crucial, a video borescope with high-definition imaging and recording features is ideal. Look for scopes with advanced articulation to navigate complex engine geometries and capture precise visuals.

For automotive maintenance, a flexible engine scope with a mid-range probe diameter (around 5.5mm) and adjustable LED illumination is best suited. Wireless options provide added convenience for mobile inspections, allowing technicians to perform diagnostics without being restricted by cables.

Heavy machinery inspections require durable, industrial-grade engine scopes with reinforced cables and waterproof construction. Longer probes (up to 3 meters) ensure comprehensive assessments of large engines and mechanical systems.

Top Engine Scopes for Internal Inspections

The Depstech Wireless Endoscope is a versatile and affordable option for basic engine inspections. It offers HD imaging, wireless connectivity, and compatibility with smartphones and tablets, making it suitable for automotive and general-purpose diagnostics.

For more advanced applications, the Olympus IPLEX GX/GT Video Borescope provides industry-leading image clarity, 360-degree articulation, and rugged construction. It is ideal for aerospace and industrial environments requiring the highest levels of precision and durability.

The Snap-on BK8000 Video Inspection Scope is a popular choice for automotive professionals. It features a compact design, intuitive controls, and high-quality imaging, making it an excellent tool for inspecting ignition chambers, valves, and other critical engine areas.

How to Perform Accurate Engine Inspections Using an Engine Scope

To ensure accurate inspections, begin by preparing the engine for assessment. Turn off the engine and allow it to cool before inserting the scope. Ensure the inspection area is free of oil, debris, and other obstructions that could interfere with image clarity.

Insert the probe carefully, using slow and steady movements to avoid damaging internal components. Adjust the illumination to enhance visibility and capture images or videos as needed. Document any signs of wear, cracks, or carbon buildup for further evaluation.

For thorough inspections, use articulated scopes to access hard-to-reach areas and examine multiple angles. Always follow the manufacturer’s guidelines for use and maintenance to extend the tool’s lifespan and ensure reliable performance.

Why Investing in the Right Engine Scope Matters

An accurate and reliable engine scope is indispensable for maintaining the integrity and performance of complex machinery. In aerospace and industrial sectors, precision inspections prevent costly failures and ensure compliance with safety standards. For automotive professionals, engine scopes streamline diagnostics, reduce labor costs, and enhance customer satisfaction.

Investing in the right engine scope not only improves diagnostic accuracy but also increases operational efficiency and safety. Whether you’re performing routine maintenance or addressing critical issues, a high-quality engine scope is an essential tool for achieving precise, reliable results.

For cutting-edge inspection tools and advanced engineering solutions, visit epci.ng – your trusted partner for innovation in engineering diagnostics.