Imagine being on a mission-critical project and discovering that a crucial component in your hydraulic system is failing—not because of a design flaw or wear, but due to the installation of a counterfeit gear pump. In the world of engineering, procurement, and construction, every minute of downtime translates into significant financial losses and jeopardized project timelines. With over 25 years of hands-on experience in the EPCI sector, I have witnessed firsthand the adverse impacts of counterfeit components on project integrity and profitability. This article is dedicated to equipping Nigerian engineers and industry professionals with the insights necessary to differentiate genuine gear pumps from their imitations, thereby avoiding costly mistakes that can derail even the most meticulously planned projects.

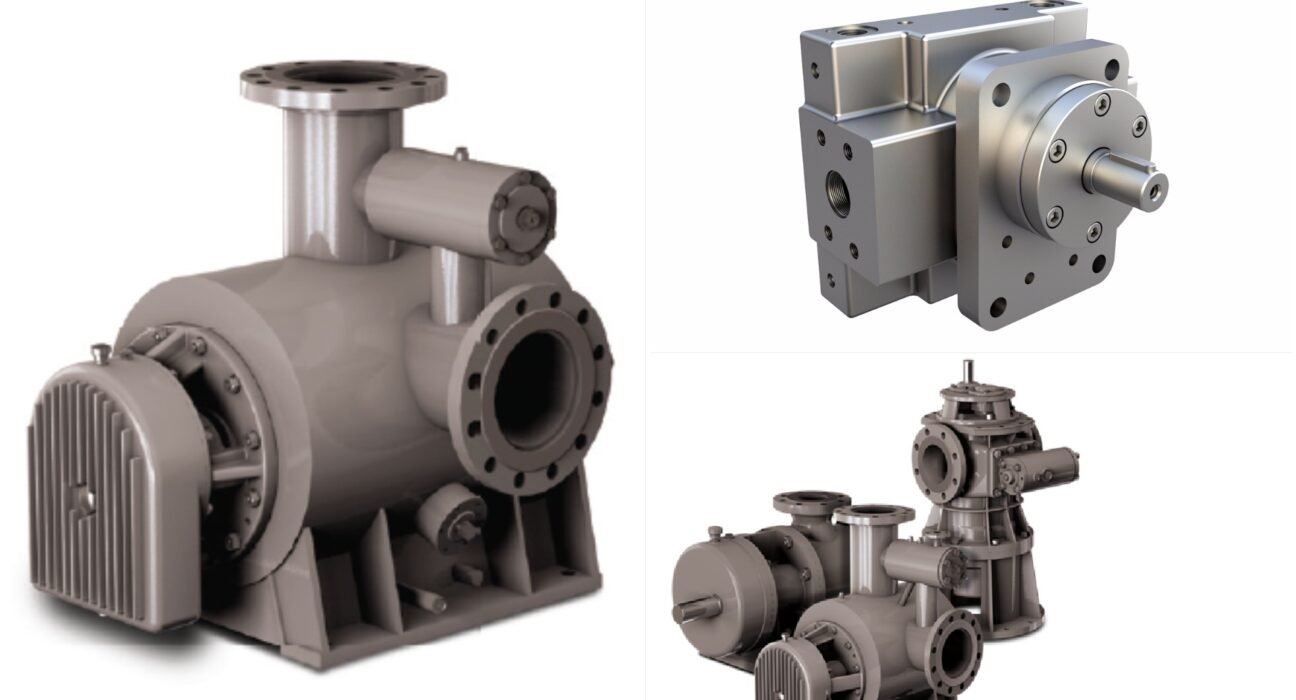

When evaluating gear pumps, one must begin with an understanding of the precision and quality inherent in genuine products. Authentic gear pumps are engineered using superior materials and advanced manufacturing techniques that ensure consistent performance and durability under extreme operating conditions. The robustness of these pumps is not merely a byproduct of high-grade materials but is also reflected in the precision of machining, the quality of seals, and the integration of safety features that comply with international standards. Counterfeit versions, on the other hand, often lack the rigorous quality control processes and detailed engineering oversight, resulting in components that may appear superficially similar yet fail to perform reliably over time.

The identification of genuine gear pumps relies on several key characteristics that experienced professionals can detect through careful examination and due diligence. One of the most critical indicators is the presence of verifiable certifications and detailed documentation that accompany the product. Authentic manufacturers invest in quality assurance protocols that include comprehensive testing, traceability of materials, and adherence to globally recognized engineering standards. These certifications are not merely formalities but are a testament to the pump’s ability to withstand the rigorous demands of industrial applications. In contrast, counterfeit gear pumps may lack this level of documentation, and any claims of certification should be scrutinized with a healthy dose of skepticism.

Material quality and the manufacturing process play a pivotal role in the long-term performance of gear pumps. Genuine products are built with alloys and hardened materials that are selected specifically for their resistance to wear and corrosion. The intricate design of these pumps is optimized through iterative testing and computational analysis, ensuring that every component functions in harmony under variable loads and pressures. When a pump is sourced from a reputable manufacturer, engineers can rely on its design integrity to deliver optimal efficiency and reliability. Conversely, counterfeit pumps are often manufactured using substandard materials, with shortcuts taken during production that compromise their mechanical properties. These compromises not only reduce the lifespan of the pump but can also lead to catastrophic failures during operation.

In today’s globalized market, the proliferation of counterfeit components is an issue that transcends geographical boundaries and affects industries worldwide. Nigerian engineers, in particular, must navigate a market where the lure of lower costs can sometimes obscure the hidden risks associated with subpar products. A genuine gear pump is an investment in the reliability and safety of a project, and the short-term savings achieved by opting for a counterfeit version can lead to long-term financial and operational setbacks. The importance of engaging with trusted suppliers who have a verifiable track record cannot be overstated. It is crucial to conduct thorough research, seek recommendations from industry peers, and request detailed performance data and test reports before making procurement decisions.

A further point of distinction between genuine and counterfeit gear pumps lies in their design and engineering innovation. Authentic gear pumps are the result of years of research and development, often incorporating patented technologies and design improvements that enhance efficiency, reduce energy consumption, and extend service life. These advancements are the product of continuous feedback from real-world applications and rigorous testing under diverse conditions. In contrast, counterfeit products typically mimic only the superficial appearance of innovative design, lacking the underlying technological improvements that drive superior performance. This gap in engineering innovation can result in significant operational inefficiencies and increased maintenance costs, making it imperative for professionals to be vigilant in their selection process.

The decision to invest in genuine gear pumps should be viewed not just as a matter of product selection, but as a strategic move that safeguards project success and financial stability. With an industry that demands the highest standards of performance and reliability, understanding the nuances between authentic and counterfeit components becomes essential. Whether you are a seasoned project manager, a procurement specialist, or an engineer on the front lines, the ability to discern quality can prevent the costly errors that so often plague large-scale projects. The insights shared here are derived from decades of experience and a deep commitment to engineering excellence, and they serve as a call to action for all professionals in our field to prioritize quality over short-term gains.

If you found these insights valuable and wish to continue exploring advanced topics in innovation, production, and industrial engineering, I encourage you to sign up and join our community at epci.ng. By subscribing, you will gain access to a wealth of expert advice, technical deep dives, and the latest industry trends designed specifically for professionals navigating the complexities of modern engineering projects. Let us work together to drive progress, ensure quality, and foster a future where engineering decisions are informed, strategic, and ultimately, successful.