The aeronautical industry is embracing digital twin technology as a game-changer in Engineering, Procurement, Construction, and Installation (EPCI) projects. Digital twins, which create real-time virtual replicas of physical assets, are revolutionizing the way aircraft are designed, built, and maintained. This advanced technology is enabling engineers to optimize performance, enhance safety, and reduce operational costs across the entire lifecycle of aeronautical projects.

One of the most significant impacts of digital twins in aeronautical EPCI is in predictive maintenance. By collecting and analyzing real-time data from aircraft sensors, digital twins provide detailed insights into component health, enabling proactive maintenance strategies. This reduces downtime, prevents costly failures, and enhances overall fleet reliability. Airlines and maintenance providers can now shift from reactive maintenance models to data-driven, predictive approaches that improve efficiency and extend asset longevity.

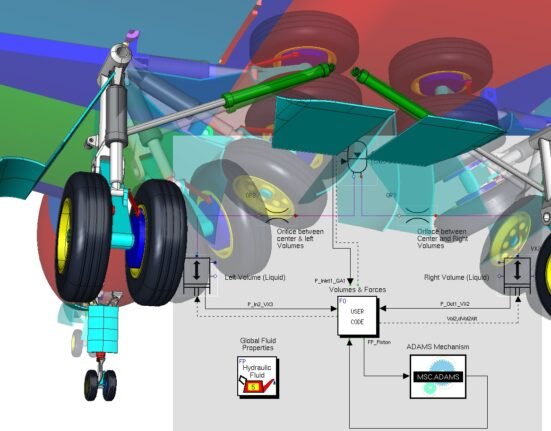

In the design and manufacturing phase, digital twins allow engineers to simulate and test aircraft components before physical production. This virtual prototyping reduces the need for expensive physical testing, accelerates the development process, and ensures compliance with stringent aviation regulations. By integrating digital twins with AI-driven analytics, manufacturers can identify design flaws early, optimize aerodynamics, and enhance fuel efficiency, leading to more sustainable aircraft solutions.

Digital twin technology is also transforming construction and installation processes in aeronautical EPCI. By creating highly detailed virtual models of aircraft components and assembly lines, project managers can identify potential challenges before they arise, streamline workflows, and improve collaboration among teams. This reduces project risks, enhances quality control, and ensures timely delivery of aerospace projects.

The implementation of digital twins in aeronautical EPCI does come with challenges, including high initial costs, data security concerns, and the need for specialized expertise. However, organizations that invest in this technology are gaining a competitive edge by optimizing asset performance, reducing operational risks, and driving innovation in the aerospace industry.

Stay ahead in aeronautical EPCI with the latest advancements in digital twin technology. Subscribe to EPCI.ng for expert insights, industry trends, and groundbreaking developments shaping the future of aerospace engineering.

Leave feedback about this